| [ Q-Car Home ] [ What's New ] [ Product Listings ] [ Ordering ] [ Information ] [ About Us ] |

|

|

|

Pole Mounting

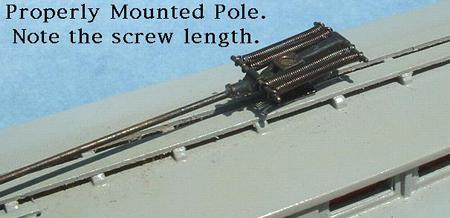

Mounting poles depends on the roof material. Assuming your car roof is wood this is the procedure: After you locate and cement the pole base on the roof walk, drill a 1.7 mm (about 1/16") hole in the roof. This hole must be square to the roof - use a drill press if possible. You can tap this hole with a 2-56 tap, or you can try to run the 2-56 x 3/4" screw that comes with the pole into this hole from inside the car. A washer should be used to keep the screw from imbedding itself in the soft wood. To this you can solder a motor lead. Now AFTER you do your soldering, put a drop of ACC cement (the liquid type) near the head of the screw. This will keep it from backing out. Turn the car over and run the pole down onto the screw to a position that leaves at least one thread under the pole. If a lot of screw is protruding out the top of the pole use a cutoff wheel on a Dremel tool to remove it. Now back the pole off the screw and carefully file any sharp edges off the screw, or use your Dremel with a wire wheel to dress down the end of the screw. You want the pole, or a nut in place when you do this cutting because the cutoff wheel may damage some of the treads. If this happens when you back the pole or nut off the screw it will restore the damaged treads. A small solder lug can be made from a small flat strip of brass. This will make it easier to wire your pole to the mounting screw. Start with a strip of .125 wide brass. Thickness can be anything from .010 to .032. We recommend .015. Drill two holes. One for the pole screw one for the wire. These holes can be about .01875 inches apart. Put a slight bend between the two holes cut the strip to length and you have your solder lug. You can taper the strip at the small hole end, but that isn't necessary. On metal roofs, it is more complicated, since you must insulate the screw from the car body. You would need some sort of insulating bushing, but the elements are the same. The main "trick" is to make the mounting screw rigid. If you have specific questions regarding this just send us an email. Another method of pole mounting is explained by Bill Becwar at "Trolley Pole Mounting - the Becwar Method".

Pole Hook Mounting As for the pole hook, what we do is drill a small hole between the fake mounting nuts on the pole hook, solder a piece of either .025 or .032 brass wire in this hole flush with the top of the pole hook; this is then inserted in a hole in the car roof. The wire is bent over inside the car. Some AC is applied to the base of the pole hook when it contacts the roof walk and a drop is put on this wire, either inside or outside where it enters the roof. The pole hook will never leave the car. You can mount the hook first, then drill the hole through the pole hook and roof. When you solder the wire, the glue will soften and probably fail, but the hook, and wire will be in the proper relationship to the roof walk. Just pull the hook and wire out of the hole, clean the burned ACC off the hook, sand the roof walk, then re-apply some ACC and re-position the hook and wire to the car. In any of this work a good ACC cement is essential. We use JET and Super Jet. |

| [ Back to Top ][ Q-Car Co. - Home ][ contact@qcarcompany.com ] | Page Last Modified: 23-Mar-24 3:58 PM |